(Image: General Atomics Electromagnetic Systems)

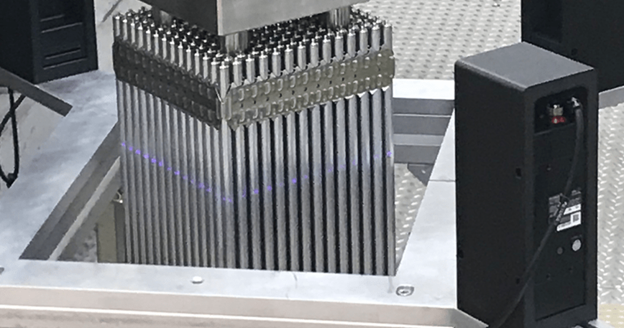

General Atomics Electromagnetic Systems (GA-EMS) announced last week that unfueled test rods featuring the company’s SiGA fuel cladding—made of a silicon carbide composite material—successfully survived 120 days of irradiation in the Advanced Test Reactor (ATR) at Idaho National Laboratory.

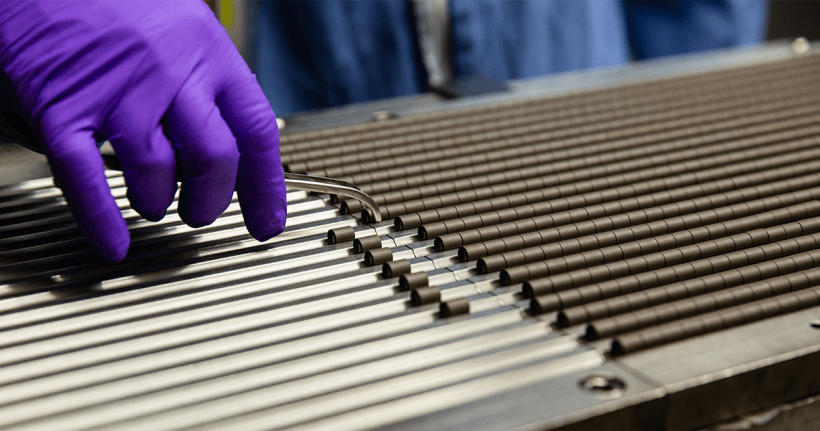

Framatome’s GAIA Protect EATF assembly. (Photo: Framatome)

Framatome’s enhanced accident tolerant fuel assemblies recently completed a third 18-month fuel cycle at Southern Nuclear’s Vogtle-2 plant—the first of this type of fuel to reach this milestone in the U.S., the company said.

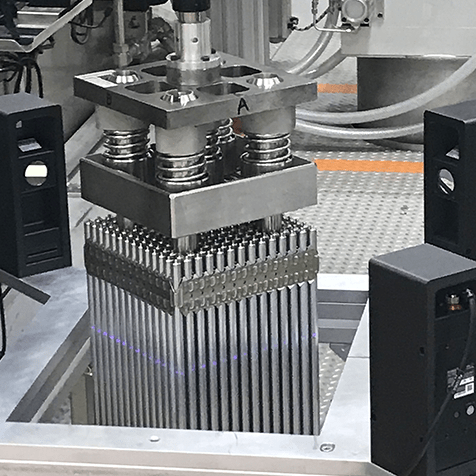

Westinghouse ADOPT fuel pellets. (Photo: Westinghouse)

Westinghouse Electric Company announced Aug. 8 that it has completed the first pressing of ADOPT nuclear fuel pellets at the company’s Springfields Fuel Manufacturing Facility in the United Kingdom. The pellets, which can contain up to 8 percent uranium-235 by weight, are destined for irradiation testing in Southern Nuclear’s Vogtle-2 pressurized water reactor.

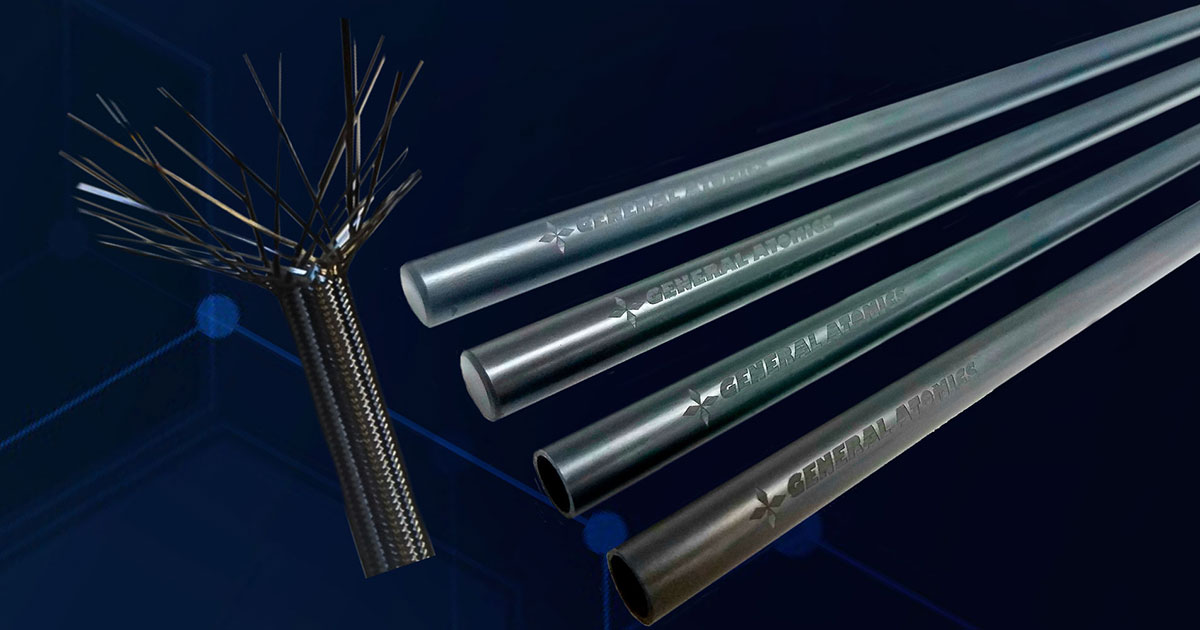

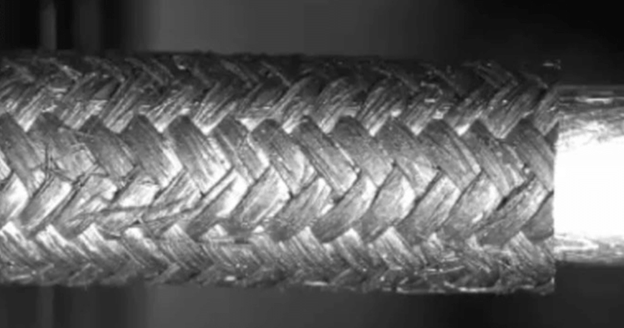

SiGA woven silicon carbide nuclear fuel cladding. (Photo: DOE)

Because of its hardness and its hardiness in the face of high temperatures, silicon carbide has been used for industrial purposes for decades. It has proven its worth as a key component of tiny TRISO fuel particles. But SiC has a weakness—in its pure form it is too brittle for use in structural components, such as 12-foot-long light water reactor fuel cladding tubes.

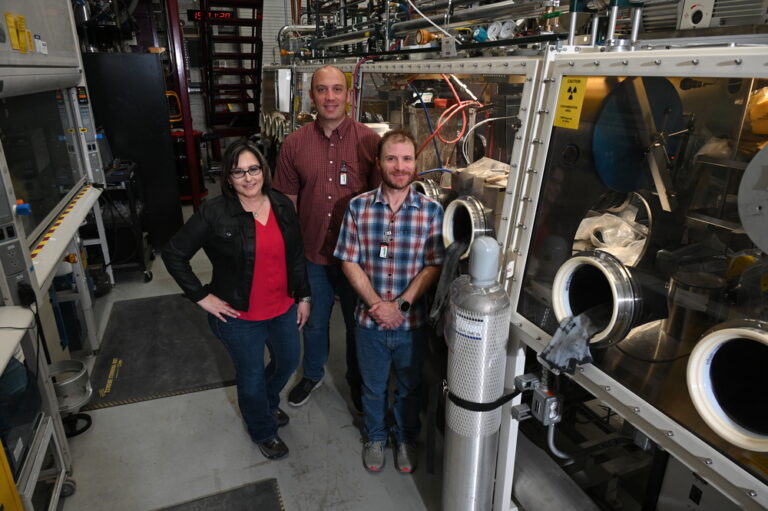

The project team included (from left to right) Jennifer Watkins, Seth Ashby, and Adrian Wagner. (Photo: INL)

Researchers at Idaho National Laboratory in early 2023 manufactured commercial-grade high-assay low-enriched uranium (HALEU) fuel pellets to the specifications of a General Electric accident tolerant fuel design, INL announced November 21. A team working at INL’s Experimental Fuels Facility at the Material and Fuels Complex fabricated about two dozen uranium dioxide pellets using HALEU enriched up to 15 percent U-235.

Framatome’s GAIA fuel assembly with Protect EATF technologies. (Photo: Framatome)

Framatome has completed the second 18-month cycle of its GAIA Protect Enhanced Accident Tolerant Fuel (EATF) technology at Vogtle’s Unit 2 in Waynesboro, Ga. Inspections afterward revealed that the full-length chromium-coated fuel rods maintained their original characteristics, while the chromia-enhanced pellets operated as designed during 36 months of reactor operation.

ADOPT fuel pellets developed by Westinghouse through the DOE's Accident Tolerant Fuel Program. (Photo: Westinghouse)

Westinghouse Electric Company and Southern Nuclear have agreed to a plan to install four Westinghouse lead test assemblies in Vogtle-2, a 1,169-MWe pressurized water reactor located in Waynesboro, Ga. Four lead test assemblies containing uranium enriched up to 6 percent U-235 will be loaded in Vogtle-2 in 2023, marking the first time that fuel rods with uranium enriched above 5 percent U-235 are put in use in a U.S. commercial power reactor.

The Nuclear Regulatory Commission last Friday announced the publication of its

The Nuclear Regulatory Commission last Friday announced the publication of its